The Manchester Aerosol Chamber - Facility Description

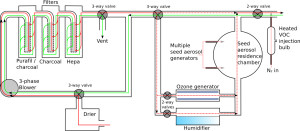

Fig 1: Schematic description of the fill-flush system of the Manchester aerosol chamber

The Manchester aerosol chamber is run as a batch reactor where the composition of the gaseous precursors, pre-existing seed, oxidising environment, relative humidity and temperature is controlled. The chamber comprises an 18 m3 (3m (H) x 3m (L) x 2m (W)) FEP Teflon bag mounted on three rectangular extruded aluminium frames. The central rigid rectangular frame is fixed, with the upper and lower frames free to move vertically causing the bag to expand and collapse as sample air is introduced and extracted, ensuring maintenance of a slight positive pressure throughout each cycle and minimizing contamination from laboratory air. A bank of halogen lamps and a 6 kW Xenon arc lamp are mounted on the enclosure housing the bag which is coated with reflective “space blanket” serving to render the enclosure as an integrating sphere, maximising the irradiance in the bag and ensuring even illumination. The combination of illumination has been tuned and evaluated to replicate the atmospheric actinic spectrum. Air conditioning between the enclosure and the bag removes additional unwanted heat generated by the lamps. The air charge in the bag is dried and filtered for gaseous impurities and particles, prior to humidification with ultrapure deionised water.

An aerosol generation system and heated gaseous charge injection port allow control of the experimental initial input concentrations of seed aerosol particles and parent VOCs. NOx levels are controlled by injection from a cylinder into the charge line and a high capacity O3 generator can control initial O3 concentrations as well as serving as a cleaning agent during flushing between experiments. Cycling between experiments is facilitated by full computer control and monitoring of key chamber conditions. Automatic fill / flush cycling to clean the chamber before and after each used experiment with 3m3 min-1 flow of scrubbed, dried, rehumidified (and optionally ozonised) air is achieved by control of electro-pneumatic valves. Each cycle takes 12 minutes and cleaning is normally achieved after 5 or 6 cycles. Coupling morning and evening cycling with overnight soaking at ppm levels of O3, allows experiments to be carried out on subsequent days. Longer experiments are possible on 2-day cycles. RH and T are measured at several points throughout the chamber (by dewpoint hygrometer and a series of thermocouples and resistance probes) and are controlled by diverting air through the inlet humidification circuit and by controlling the air conditioning setpoint. This controls the conditions throughout the experiment.