Single Particle Soot Photometer

Principle of Operation

The operation of the SP2 is based around the light absorbing property of soot. Particles are drawn into the measuring chamber through a capillary, restricted with a particle free sheath flow and focussed into a jet. Further particle free air is used as a purge flow to keep optical components free from contamination. The particle jet passes through the centre of an intra-cavity laser beam operating at 1060nm. Particles passing through the beam scatter laser light into a detector, allowing particle size to be determined in the same way as in other optical sizing instruments (opc). Particles which contain absorbing material absorb as well as scatter laser radiation. The intensity of radiation in the beam is sufficient to heat and vaporise absorbing material as the particle passes through the beam. As absorbing particles heat up, they emit a broad spectrum of radiation (black body radiation) which peaks at a wavelength characteristic of their temperature.

Particles whose boiling point temperature is sufficiently high that they emit visible light are said to incandesce, with the colour of light emitted indicative of the boiling point temperature of the particle. Two detectors which are sensitive to different wavelength bands (350-800 and 630-800nm) are used to detect light emitted during incandescence. Thus particles which absorb laser energy, and have a high enough boiling point are detected as incandescing particles, and their colour temperature determined. The intensity of incandescence is proportional to the mass of material incandescing. In the atmosphere black carbon (soot particles) is the most abundant material which will incandesce; other materials which incandesce include various metals. However as boiling point temperatures of these materials are rather different to that of black carbon it is easy to distinguish them in measurements made using the SP2. Particles which consist of a mixture of soot and other material will still incandesce, with the intensity of incandescence still proportional to the mass of incandescing material, but other material present will be vaporized before the soot reaches incandescence. The presence of such material delays slightly the onset of incandescence.

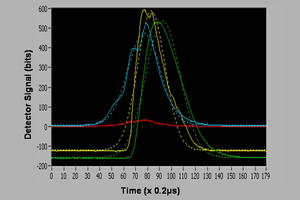

The SP2 data system processes signals from four separate detectors, which are simultaneously sampled at 5MHz. Each time a particle is detected, the system records a fixed number of data points (around 200) on all four channels. Thus a complete record of scattering and incandescence pulses are retained for each particle sampled. Additionally a large number of instrument housekeeping parameters such as temperatures, pressures, flows and detector voltages are recorded each second. Particle data is processed to provide scattering intensity, two channels of incandescence intensity, and time delays between the various signals. These parameters allow particle size, incandescence colour temperature and mass to be determined. Additionally it is possible to determine the mixing state of single particles from both the ratio of optical scattering and incandescence masses, and from the time delay between scattering and incandescence signals. This area of work is quite new, and research is still ongoing into how accurately coating thicknesses, or other mixing states can be determined from these measurements. The ratio technique may be affected by material being lost from the particle before the peak scattering signal is reached, and it is expected that time delays will also be sensitive to the intensity of radiation illuminating the particle. Further developments of the instrument are being implemented to allow single particle mixing state to be investigated further, in particular, a split detector is being installed, which allows the position of the particle relative to the centre of the laser beam to be determined, and hence the intensity with which it has been illuminated to be quantified.