Condensation Particle Counters (CPC)

In a supersaturated vapour suspended particles act as nuclei for vapour condensation and may grow to form droplets. This process is referred to as heterogeneous nucleation. Above a critical supersaturation droplets may form by homogeneous nucleation where clusters of vapour molecules nucleate droplets. Supersaturation is defined as the actual vapour mixing ratio divided by the saturation vapour mixing ratio at that temperature, and is generally expressed as a percentage. The critical supersaturation for homogeneous nucleation is typically around 300%. Droplets may form heterogeneously at supersaturations of less than 1%. This is the process by which clouds form in the atmosphere. The size of aerosol particles which will act as condensation nuclei is a function of the supersaturation it experiences. The smallest size at which condensation will occur at a particular supersaturation is referred to as the Kelvin diameter. This size dependence is because saturation vapour pressure is defined relative to a flat liquid surface. Vapour molecules are able to escape more easily from a curved surface, thus the saturation vapour pressure is increased with decreasing radius of curvature. The Kelvin diameter is the diameter at which a pure liquid droplet is in equilibrium with the vapour phase at that supersaturation.

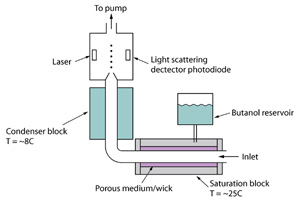

In a CPC, supersaturation is carefully controlled to a high value, typically 100-200%, but below the critical supersaturation so that droplets do not form in particle free air. There are a number of techniques by which such supersaturations may be achieved, including adiabatic expansion, flow mixing, and diffusional thermal cooling. Most commercially available CPC’s use the diffusional thermal cooling method.

In a counter using the diffusional thermal cooling method, particle laden air passes through a heated porous block or wick in contact with the working fluid, which is usually butanol, and becomes saturated. In some models in order to ensure that all particles experience the highest possible supersaturation which occurs along the centre of the saturator, a sheath flow is used to constrain the particles. Here the inlet flow is split into sample and sheath flows, the sheath flow is filtered and passes through the saturator wick. The sample flow is then injected into the centre of the laminar sheath flow through a capillary. On exiting the saturator, the saturated air is cooled in the condenser, becoming supersaturated and causing particles above a certain size to grow into drops. These drops are then focussed through a nozzle, and pass through the laser beam and are counted. The minimum particle size which can be detected by a CPC is determined by the supersaturation achieved, which in turn depends on the temperature difference between saturator and condenser. In practise not all particles experience the same supersaturation, and hence the efficiency of the counter gradually decreases at smaller sizes, and the lower cut-off size is defined as the size at which 50% of particles present are counted. The more uniform the supersaturation, the sharper the cut off. Particle count is generally determined by counting individual pulses of scattered light. However at high concentrations dead time becomes significant. Dead time is the time during which there is physically a particle present in the beam, or the system is already busy processing a particle, during which detection of additional particles is not possible. Some models of CPC automatically adjust the count according to measured dead time at high particle concentrations; while others use a photometric light scattering technique (i.e. particle count is related to total scattered light during the integration period).

Relatively recently CPC’s have been developed which use water as the working fluid. In these instruments supersaturation is achieved by passing the sample through a wet tube, during which it becomes saturated and the temperature of the sample reaches equilibrium with the walls. It then passes through a heated region of the wet tube, which raises the vapour pressure, as the rate of water vapour diffusion is greater than that of thermal diffusion, the sample becomes supersaturated. In other aspects water CPC’s operate in a similar manner to butanol CPC’s described above.

While CPC’s do not provide any information on the original size of particles counted, they are often used with size selecting devices such as Differential Mobility Analysers for example in the Differential Mobility Particle Sizer, so that size distribution information can be built up. Additionally several CPC’s with different lower cuts can be used to provide a course, but fast response size distribution of small particles.

The response time of most commercial CPC’s is typically 1s, which is not fast enough for most eddy covariance applications, though some newer models have 10hz data output. However, most also output raw pulses from the detection system, which with appropriate external processing allow eddy covariance flux measurements to be made. Again using multiple CPC’s fluxes of ultrafine particles in specific size ranges can be measured. This is especially useful for studies of new particle formation processes, and urban emissions.

The Centre for Atmospheric Science currently owns twelve CPC’s manufactured by TSI Inc., including several new water based CPC’s, one of which has been specially modified for aircraft use.